Burger King improves efficiency and productivity in a fast-paced restaurant

Every part of the process is measured, also the waste handling

Burger King saves time and increases efficiency with Mil-tek

Efficiency is key for Burger King as they use Mil-tek to improve efficiency and productivity in their fast-paced restaurant.

Using a Mil-tek solution to bale their cardboard keeps their staff indoors, focused on customers and keeps their kitchen and store room areas clean and hygienic.

Flame grilling since 1954

Burger King is an American fast-food chain that was the first large chain to open in Denmark in 1977. Burger King Corporation operates in 67 countries approx. 12,000 restaurants.. The company has 360,000 employees worldwide. Every day, Burger King has 11,400,000 customers, so each branch has an average of 1,040 customers per day.

Efficiency is key

For Burger King, efficiency is key to their workflow. Every part of the process is measured across all of the food-producing workstations to the pick-up points through to the drive-thru and back-of-house.

Decreasing the time each process takes contributes to increasing the overall efficiency of the restaurant. Removing unnecessary parts of a process is significantly better again.

Identifying the issues

Prior to partnering with Mil-tek, the restaurant used 3 small waste containers in the backyard into which the staff placed all waste. Once the containers were filled, they would be emptied by a waste handler who came and emptied the bins.

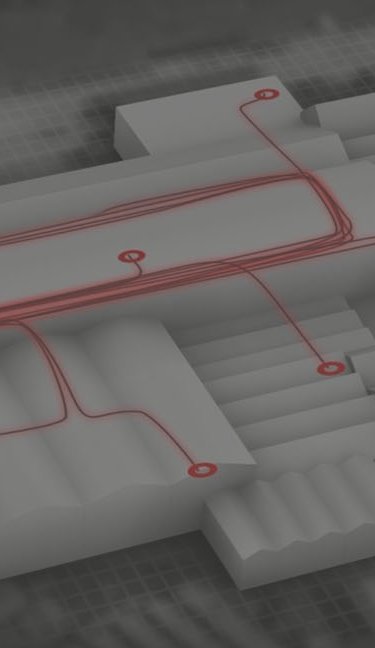

With such a strong focus on efficiency, it was quickly identified that the entire waste handling process needed an overall. It was determined that the most effective solution would be a Mil-tek A305 baler placed inside the storeroom to handle the large volume of cardboard being produced.

Optimising the process

Installing a Mil-tek cardboard baler had a number of immediate benefits. Not having to carry waste outside to an external container meant that the backdoor of the storeroom could stay closed. This kept the temperature regulated and improved the cleanliness of the storeroom.

Recyclable waste was immediately placed into the baler, meaning the staff longer had to flat-pack it or leave it to pile it up by the door. As a result, the storeroom area was immediately neater and tidier, and the waste was dealt with immediately rather than in two separate steps.

Have a question?

Get in touch today to learn more about how Mil-tek can help your business save time, space and money by better handling waste

Get info about a product or have a chat with one of our local reps. Let us know what you need so the right person can get in touch