How does a baler for recycling work?

Not sure how a recycling baler works, or what models are available? Read this Guide to learn more.

What does a recycling baler do?

Balers are devices used during the recycling process to compress waste material into more manageable bales.

Traditionally used in several industries, including schools, retail, restaurants and manufacturing, balers make waste disposal safer and more manageable.

There are several types of balers – let’s have a look:

Heavy duty balers

Heavy duty balers are among the most powerful machines used in modern waste management. Designed for applications where standard equipment is not enough, these balers generate the extreme pressure required to compact tough and bulky materials. In fact, many hydraulic balers fall into the heavy duty category, since their hydraulic rams provide the immense force needed for maximum compression. With this strength, heavy duty balers can process large and dense waste streams, ranging from cardboard and plastics to challenging materials such as rubber and tires, making them indispensable for industries that handle high volumes of tough refuse.

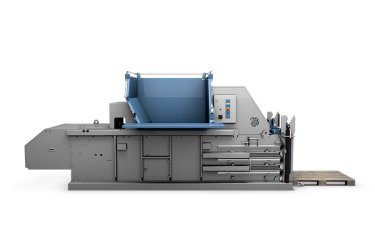

Horizontal balers

Horizontal balers are typically made up of two separate pieces: the baler itself and the conveyor belt. This design allows a continuous feed of material, making them ideal for operations that generate large volumes of waste. They’re commonly used in managing high-density waste material, as they’re intended to handle large throughputs with ease. For this reason, a horizontal baler is sometimes referred to as a “channel baling press,” reflecting its ability to produce uniform, mill-sized bales that are well suited for recycling and industrial applications.

Industrial balers

Industrial balers are large-scale machines built to handle the demanding waste management needs of businesses. While an industrial baler is often a horizontal baler, it can also be a heavy duty baler designed for especially tough materials. These machines are widely used across industries such as cardboard packaging, distribution, recycling, document destruction, and even the automotive sector.

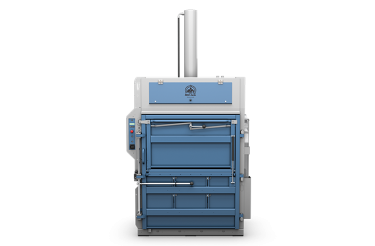

Vertical balers

A vertical baler is a standard appliance in most industrial settings.

They are typically used to manage smaller capacities of waste or recycling per hour and are, therefore, more suited to small businesses and enterprises. They help make recycling easier to transport.

Specialty balers

Organisations have the option to source a special baler devised to suit their specific needs. Some examples are sawmills or millwork plants that are likely to require a sawdust baler. Such a device is able to exert a significant amount of pressure, creating bales of paper or sawdust. In the case of companies involved in the manufacture of foam goods, a scrap baler is an optimal solution. Some companies necessitate a solution that can also remove moisture from the waste material to ensure optimal hygiene. There is also the need to safely dispose of insulation waste, where an insulation compactor can serve as a specialised option.

The goal of a baler is to dispose of refuse in a safe and orderly way. Many kinds of balers are available, and each organisation can use a different one depending on their needs.

Explore our range of waste handling solutions: Cardboard balers, plastic balers etc.

What do you want to compact?

Contact us if you want to hear more about how Mil-tek can help your company optimize your waste management.

We will get in touch as soon as possible.