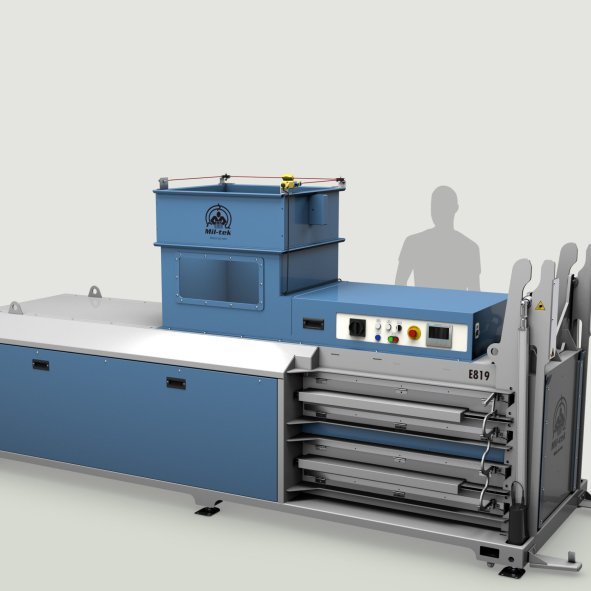

Electric balers by Mil-tek

Electric balers offer a modern, eco-friendly solution for compacting recyclable materials and waste. With a clean, oil-free design, they eliminate the risk of hydraulic fluid leaks while providing a quieter, low-noise operation ideal for indoor or noise-sensitive environments. There machines are easy to maintain, energy-efficient, and suitable for a wide range of applications, from retail and warehousing to manufacturing.

How Electric Balers work

Electric balers use a servo or motor-driven press to apply consistent force, compacting materials into dense, uniform bales. Unlike hydraulic systems, they require no oil, eliminating the risk of leaks and reducing maintenance needs.

This clean, efficient design makes them ideal for sensitive environments.

Typical bale sizes vary depending on the model, but they are engineered to maximize storage and transport efficiency, offering a reliable and eco-friendly solution for managing cardboard, plastics, and other recyclable materials.

Key benefits of an Electric Baler

Electric balers operate at noise levels below 70 dB, making them ideal for production floors and other noise-sensitive areas. Their compact footprint allows for easy placement in tight spaces, while straightforward installation minimizes downtime. With no hydraulic oil and fewer moving parts, maintenance is simple and cost-effective.

This combination of quiet operation, space efficiency, and low upkeep makes electric balers a practical and reliable choice for businesses looking to improve waste handling without disrupting daily operations.

Industries using Electric Balers

Electric balers are ideal for industries where cleanliness, low noise, and efficiency are essential. In food and beverage production, they help maintain hygiene while managing packaging waste. Pharmaceutical facilities benefit from their oil-free design, preventing contamination risks. Cleanrooms and laboratories value their quiet, dust-free operation, ensuring compliance with strict standards. Even office environments can use electric balers to compact paper, cardboard, and recyclables discreetly, without disturbing staff, making them a versatile solution across diverse, sensitive work settings.

Comparing power sources – Electric vs. Hydraulic vs. Pneumatic

When selecting a baler, the main options are electric, hydraulic, and pneumatic.

Electric balers are clean, quiet, and oil-free, ideal for sensitive environments.

Hydraulic balers deliver the highest pressing force for dense, bulky waste.

Pneumatic balers use compressed air, offering flexibility for lighter materials.

What kind of waste is our electric balers useful for

Mil-tek’s electric balers excel at compacting cardboard, plastics, and similar recyclables.

Learn more in our cardboard balers and plastic balers guides.

Frequently asked questions

What electrical supply is needed?

Most electric balers run on a standard three-phase supply, though smaller models may use single-phase connections.

How does noise compare?

Electric balers operate quietly, typically below 70 dB, making them suitable for noise-sensitive environments.

Are there oil-free certifications?

Yes, many electric balers carry certifications confirming their oil-free, contamination-safe design.

What’s the typical cycle time?

Cycle times generally range from 30 seconds to a few minutes, depending on the model and material type.

Have any questions?

Electric balers offer clean, quiet, and efficient waste compaction for sensitive environments.

Book your free site audit today to find the perfect fit for your operation.