Construction waste management and disposal solutions

This page presents end-to-end waste solutions for construction, renovation, and demolition projects that make it possible to reduce waste volume by up to 90% and increase debris recycling.

How to recycle building and renovation debris

Construction and renovation projects generate vast amounts of waste, typically collected in multiple skips or open containers that fill up quickly.

Mil-tek delivers robust, site-ready solutions that reduce waste volume and container pick-ups, helping your team stay focused on the job instead of handling waste.

✅ Get a free waste review of your next project

→ Talk to a Mil-tek consultant

✅ Browse balers that suit your site and material mix

→ Browse our solutions

Overflowing construction waste: Hidden costs and hazards

A building site often has several containers for different waste streams, with little real sorting. Overflowing skips are common as well, and debris often ends up blowing across the site.

Furthermore, multiple containers require frequent pick-ups and emptying, sending trucks back and forth and driving up costs. This can also create safety hazards for workers.

📌 Construction waste that isn’t managed efficiently stalls schedules, inflates project costs, and eats up valuable site space – quietly eroding your profit margin.

Minimize construction waste where it is generated

By compacting cardboard, plastic, EPS, and mineral wool off-cuts at the point of generation, you reduce waste volume by up to 90 %.

This leads to:

- Fewer skip swaps

- Lower haulage fees

- Less truck traffic

- No windblown waste

- Easier on-site storage

- More efficient truck loading

- Tidier, safer work areas

- Crews focused on the job, not waste handling

Construction and Demolition Waste Solutions

Book a free waste audit to discover how to cut skip-bin costs and clear valuable space on your jobsite.

Or explore our range of balers and compactors below, built to handle the types of debris that pile up on every construction and renovation project:

Handle cardboard and plastic packaging on-site

With a baler placed directly on the construction site, cardboard and plastic are compacted instantly by up to 90 %.

This reduces manual handling for your crew and cuts down significantly on container collections.

See baler recommendations below:

A406 Vertical Baler

Usage:

Cardboard & Plastic

Power:

Pneumatic, 8 tonnes pressing force

Key Attributes:

- • Up to 225 kg bales

- • 90 % compaction

- • Wide chamber for larger materials

- • Runs on a 110-volt compressor

A509 Vertical Baler

Usage:

Cardboard & Plastic

Power:

Pneumatic, 8 tonnes pressing force

Key Attributes:

- • Up to 300 kg bales

- • 90 % compaction

- • Auto bale-out function

- • Runs on a 110-volt compressor

E519 Vertical Baler

Usage:

Cardboard & Plastic

Power:

Electric, 18 tonnes pressing force

Key Attributes:

- • High compaction pressure

- • Dense bales of up to 230 kg

- • Wide loading chamber

- • Auto-start

Compact EPS / Polystyrene offcuts

EPS is common in construction, but it fills containers fast due to its bulky, lightweight form.

On projects with high EPS waste, a polystyrene compactor on-site can reduce volume by up to 40:1, cutting skip collections and freeing up space.

See recommended options below:

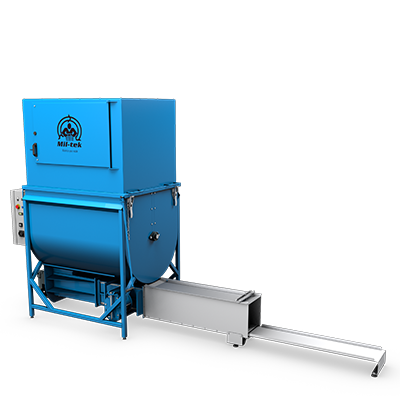

EPS1000 EPS Compactor

Usage:

Polystyrene / EPS

Power:

Electric, 1,8 kW

Key Attributes:

- • EPS volume reduction of 40:1

- • Blocks of up to 300 kg per m3

- • Compacts up to 15 kg. per hour

- • Install on site

EPS2000 EPS Compactor

Usage:

Polystyrene / EPS

Power:

Electric, 2 x 3 kW

Key Attributes:

- • EPS volume reduction of 40:1

- • Blocks of up to 300 kg per m3

- • Compacts up to 70 kg. per hour

- • Install on site

Don’t let debris clog your job site or delay your schedule!

Book a free construction-site survey with Mil-tek. Our experts will assess your setup and suggest the ideal waste-handling approach for your project.

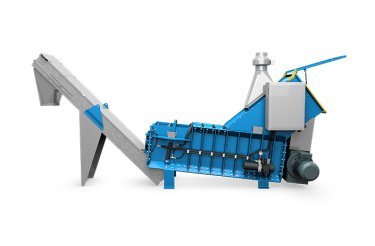

Compact mineral wool and insulation on site

Stone wool, mineral wool, and similar insulation materials can be difficult to handle and often scatter in the wind on the site.

This insulation compactor compacts over 500 kg of mineral wool and insulation per hour with continuous loading and 100% recyclable output.

Watch the video!

Get a plug-and-play solution with the IC60 compactor in a container, mobile, ready to handle insulation waste on-site

Get in touch 📞

Reach out and we’ll help you build the right waste solution for your project.

Simply fill in the form or call us.