Waste Management for Logistics & Warehousing

This page presents effective strategies to cut waste, improve storage efficiency, and lower operating costs in the logistics and warehousing sector.

Logistics waste management

In logistics, large volumes of waste – especially cardboard and plastic – are generated daily as goods are received, unpacked, and repacked.

Without efficient handling, this waste quickly becomes a bottleneck.

Mil-tek’s high-performance balers and compactors let you tackle waste at the source and reclaim valuable space.

✅ Get tailored advice for your facility

→ Talk to a Mil-tek logistics specialist

✅ Explore balers for cardboard, stretch-wrap, mixed recyclables etc.

→ Browse all balers & compactors

The real impact of waste in logistics

Cardboard, plastic, and packaging waste build up fast in logistics environments, slowing down operations and cluttering busy workspaces.

Staff waste hours hauling waste across the site several times a day instead of focusing on critical tasks.

📌 Waste that isn’t handled efficiently leads to delays, higher costs, and wasted space – and quietly drain annual revenue.

Managing waste efficiently in the logistics sector

Mil-tek solutions are designed to be installed right where waste is generated, near packing stations, inbound docks, or sorting areas. This means your team can dispose of waste immediately, keeping the flow moving without disruptions.

By placing right-sized balers and compactors at the waste source, logistics facilities can:

- cut waste volume by up to 90%

- reduce haul-away runs

- free up valuable floor space in busy aisles

- reduce manual handling and save labour hours

- transform recyclables into a revenue-generating stream

Waste Management Solutions for Logistics & Warehousing

Book a free waste audit to uncover the most efficient waste strategy for your facility.

Or explore our range of balers and high-volume compactors, designed for the waste streams that dominate logistics sites below:

Keep aisles clear with heavy-duty balers for logistics

Efficient waste management in logistics requires both scale and automation.

Mil-tek delivers with robust vertical and horizontal balers designed to compact large volumes of cardboard and plastic.

Explore our high-volume balers below:

A509 Vertical Baler

Usage:

Cardboard & Plastic

Power:

Pneumatic, 8 tonnes pressing force

Key Attributes:

- • Up to 300 kg bales

- • 90 % compaction

- • Wide door and large pressing chamber

- • Auto bale-out function

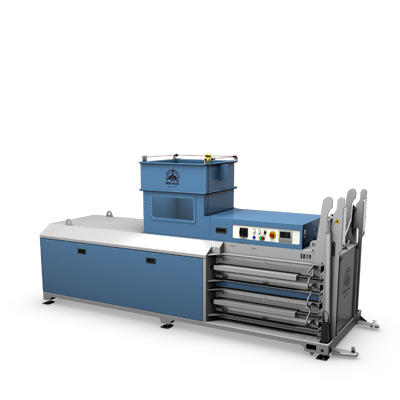

E819 Horizontal Baler

Usage:

Cardboard & Plastic

Power:

Electric, 25 tonnes pressing force

Key Attributes:

- • Up to 400 kg bales

- • 90 % compaction

- • 5 m² footprint

- • Continuous filling / automatic start

H600 Vertical Baler

Usage:

Cardboard & Plastic

Power:

Hydraulic, 60 tonnes pressing force

Key Attributes:

- • Hydraulic: extremely dense bales

- • Mill size bales of up to 500 kg

- • Automatic door operation & bale ejection

- • Noise Level: 70 db(A)

Watch the video!

Horizontal baler in action at a logistics centre

This logistics site generates up to 40 cages of cardboard daily – previously requiring a full-time operator just to manage the waste.

Since installing Mil-tek’s E819 baler, up to 20 cages can be loaded before a bale-out is needed. This has reduced manual handling significantly and keeps aisles clear from cardboard and plastic.

Automated waste handling for logistics and warehousing

Add a conveyor to the E819, and packaging waste can flow directly from the packing line into the machine. No manual handling, no delays.

Perfect for high-throughput logistics hubs and busy distribution centres, it’s a smart way to save time, reclaim space, and reduce operating costs.

Polystyrene waste in logistics?

Compact it easily for maximum space savings!

If large volumes of polystyrene pass through your operations, you’re likely dealing with space shortages, cluttered work areas, and high transport costs.

Mil-tek’s polystyrene compactor shreds and compresses polystyrene at a 40:1 ratio. This turns the bulky waste into dense, recyclable blocks – cutting down on disposal costs and minimising waste handling.

Don’t let waste clog your warehouse aisles or

loading docks!

Book a free site survey with Mil-tek. Our experts will find the optimal waste solution for your logistics facility.

Baling logistics waste turns cardboard, plastic, polystyrene and more into compact, stackable bales. This frees up valuable floor space, streamlines handling, cuts transport costs, and boosts overall efficiency.

Get in touch 📞

Mil-tek helps logistics businesses take control of one of the most overlooked parts of their operation: waste. Reach out and let us help your facility cut disposal costs and keep goods moving smoothly.

Fill out the form here or give us a call.