Horizontal Baler FAQ

What is a horizontal baler and how does it work?

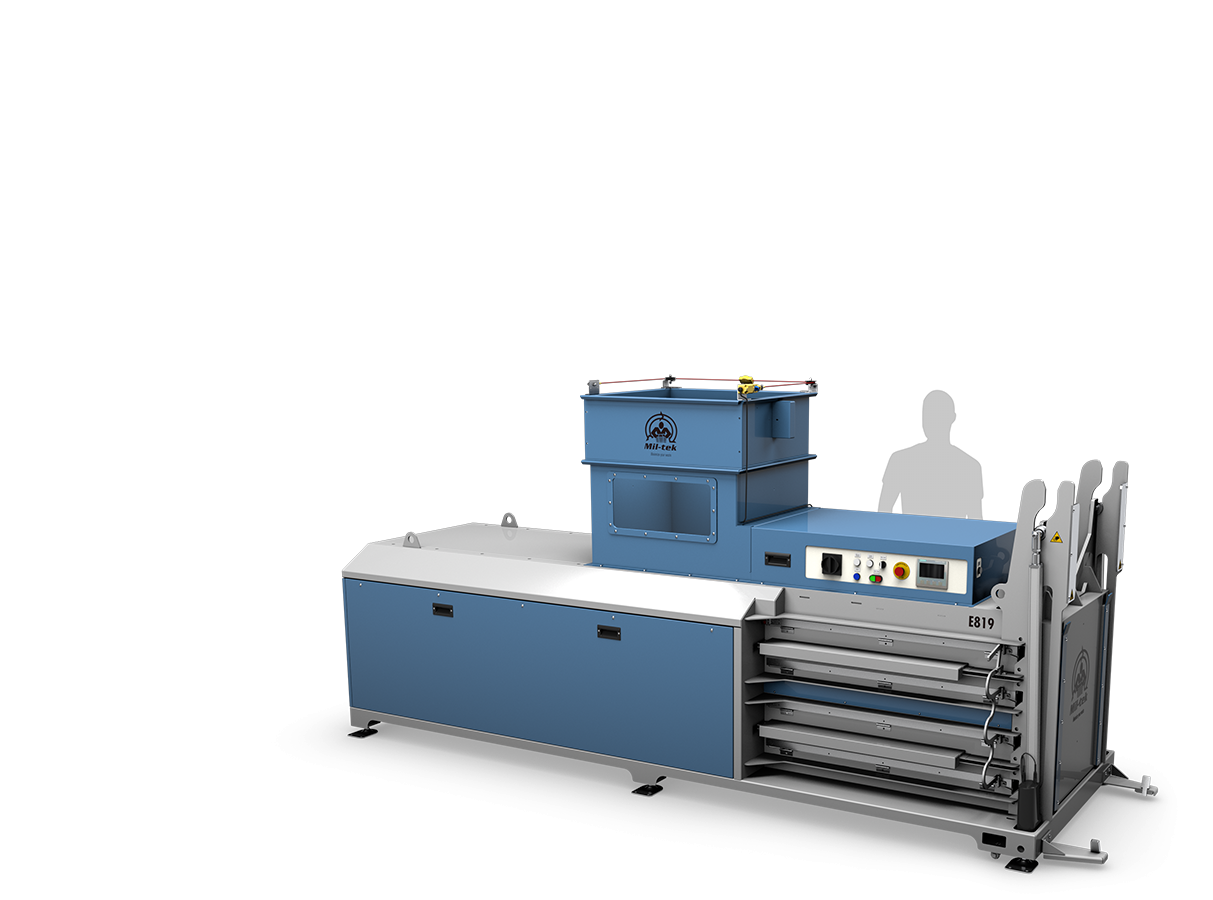

A horizontal baler compresses large volumes of recyclable waste – like cardboard and plastic – sideways into dense, stackable bales (450–1000 kg). Materials can be loaded manually or via bin tippers, conveyors, or forklift skips. With sensor or laser-eye activation, many models offer “set and forget” automation. Bales are ejected efficiently, with options for manual or fully automatic tying to save time and labor. Designed for high throughput, horizontal balers feature large hoppers and support payloads up to 24t, making them ideal for streamlining operations and maximizing recycling rebates.

Why should I choose a horizontal baler?

You should choose a horizontal baler if you need to handle large amounts of waste efficiently, want high automation, and require continuous operation with minimal manual effort.

Horizontal vs. vertical balers: Choosing the right fit

When considering space and volume, vertical balers are compact and ideal for lower waste volumes, while horizontal balers handle higher volumes but require more space. In terms of automation and throughput, vertical models need more manual input, whereas horizontal versions offer greater automation and suit continuous operations. Though horizontal balers come with a higher upfront cost, they can lower labor expenses over time. Vertical balers, with lower initial investment, may lead to increased manual handling and maintenance needs.

Not sure which baler suits you? Learn more about our vertical balers here.

How large are the bales produced by a horizontal baler?

The size of bales from a horizontal baler varies depending on the model. The weight can range from 200 kg to over 1 ton, depending on the material and compression strength.

How are bales tied in a horizontal baler?

Bales from a horizontal baler are tied with metal wire or plastic strapping, depending on the machine’s design and level of automation.

What materials can be compressed with a horizontal baler?

Cardboard, paper, plastic, hard plastic, PET bottles, textiles, and more.

How does automatic operation work on a horizontal baler?

Automatic operation in a horizontal baler means that the machine can handle automatic start upon waste loading, compression, and bale ejection without constant manual supervision.

Is my facility too small for a horizontal baler?

Not necessarily – it’s about volume, not just space. If you process 2+ tons of waste daily, a horizontal baler is worth considering. Many models are compact yet built for high throughput and reduced manual labor, making them ideal even for smaller facilities with heavy waste streams.

Can I lease a horizontal baler?

Yes, you can hire or lease a horizontal baler from Mil-tek, with flexible financing options to suit your budget and operations.

For other types of balers, visit our balers and compactors page.