Cardboard Balers

Reduce cardboard volume by up to 90%, cut collections and free up space.

With over 30 years of experience, we provide cardboard baler solutions to help your business handle cardboard waste effectively.

Save time

Reduce the time spent handling cardboard waste with Mil-tek’s efficient baling machines, allowing employees to focus on core tasks rather than waste management.

Save money

Eliminate the cost of multiple bins and frequent waste pickups by compacting waste into recyclable bales, leading to significant long-term savings and improved operational efficiency.

Save space

Compact waste by up to 90%, freeing up valuable storage space in your workplace that can be repurposed for inventory, equipment, or other critical uses.

Discover Our 3 Most Popular Cardboard Balers

A102 Small Baler

- Very small footprint, only 0.45m²

- Worlds’ fastest pressing cycle

- Bale 40 kg cardboard/100kg plastic

- Optimal working height

A509 Wide Chamber Baler

- Extra wide filling chamber

- Bale 225 kg cardboard/300 kg plastic

- Adjustable bale size

- 1.5m² footprint

Pneumatic Cardboard Balers

Pneumatic balers are the core of Mil-tek's expertise.

These machines are powered by compressed air, offering a simple, clean, and low-maintenance alternative to hydraulic or electric systems.

Their design makes them especially suited to small and medium-sized enterprises (SMEs) and retail operations, where space, budget, and ease of use are key considerations.

Get quoteElectric Cardboard balers

Low-height balers with powerful performance!

Our electrical balers for cardboard waste offer a compact design with high pressing force, making them ideal for spaces with limited ceiling height.

They efficiently compress large volumes of cardboard into dense bales, maximizing space and reducing transportation costs.

Free of hydraulic oil, these balers eliminate leak risks, ensuring cleaner, safer operations with less environmental impact and reduced maintenance.

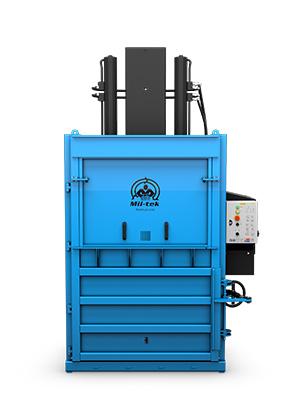

Get quoteHydraulic Cardboard Balers

If your business generates large cardboard waste streams, a hydraulic baler is the perfect heavy-duty solution.

At Mil-tek, we offer durable vertical and horizontal hydraulic balers designed specifically for businesses with significant cardboard waste streams. These machines excel in compressing heavy materials into dense, compact bales, with some models producing mill-size bales ready for recycling and optimized for transport, saving time and logistical costs.

Engineered for durability and high-capacity operations, our hydraulic balers are ideal for industries like retail, warehousing, manufacturing, and distribution.

Whether you choose a vertical or horizontal baler, these machines provide the pressing power to efficiently compact large amounts of cardboard, freeing up space and significantly reducing waste disposal expenses.

Get quoteComparison of popular cardboard balers

| A102 | A305 | A509 | E119 | E319 | E619 | H600 | H501 | 50SD | |

|---|---|---|---|---|---|---|---|---|---|

| Cardboard bale | < 40 kg | < 100 kg | < 225 kg | < 50 kg | < 80 kg | < 300 kg | 340-450 kg | 350 - 400 kg | < 500 kg |

| Plastic bale | < 100 kg | < 175 kg | < 300 kg | < 80 kg | < 100 kg | < 400 kg | 340-500 kg | 350 - 450 kg | < 520 kg |

| Pressing cycle | 6-10 sec. | 10-20 sec. | 15-25 sec. | 43 sec. | 63 sec. | 65 sec. | 36 sec. | 40 sec. | 55 sec. |

| Degree of compaction | 85-90% | 85-90% | 85-90% | 85-90% | 85-90% | 85-90% | 85-90% | 85-90% | 85-90% |

| Bale size H x W x D (mm) | 710-830 x 655 x 450 | 760-880 x 655 x 850 | 760-880 x 1250 x 835 | 710-830 x 655 x 545 | 700-800 x 900 x 500 | 800-900 x 1500 x 800 | 800 x 1200 x 1100 | 800 x 1200 x 800 | 1120/1170 x 1270 x 770 |

| Door opening H x W x D (mm) | 505 x 655 x 415 | 570 x 655 x 815 | 570 x 1250 x 800 | 480 x 630 x 500 | 600 x 900 x 500 | 550 x 1500 x 800 | 550 x 1160 x 780 | 670 x 1200 x 780 | 610 x 1140 x 770 |

| Machine size H x W x D (mm) | 2292 x 832 x 541 | 2530 x 825 x 1034 | 2530 x 1450 x 1040 | 2260 x 800 x 720 | 1855 x 1165 x 810 | 2070 x 1915 x 990 | 2170 x 1890 x 1400 | 3100 x 1600 x 1300 | 3160 x 1885 x 1105 |

| Noise level | < 70 db (A) | < 70 db (A) | < 70 db (A) | < 70 dB (A) | <60 dB (A) | <65 dB(A) | < 70 db (A) | < 70 db (A) | < 70 db (A) |

| Pressure | 2500 kg at 8 bar | 4000 kg at 8 bar | 8000 kg, at 8 bar | Up to 2.5 tonnes | 15.000 kg | 25.000 kg | <60 tons | <50 tons | 50 tons |

| Approvals | CE, EN16500, UKCA | CE, EN16500, UKCA | CE, EN16500, UKCA | CE, EN16500 | CE, EN16500, UKCA | CE, EN16500, UKCA | CE, GS & UKCA | CE, GS & UKCA | CE, EN16500, UKCA |

| Power supply | 1 x 230V/50Hz / 10 Amp | 3 X 400V / 16 Amp | 3 X 400V / 16 Amp | 7,5 kW - 3x400V - 25 Amp | 7,5 kW - 3x400V - 25 Amp | 7,5 kW - 3x400V - 25 Amp |

Horizontal baler for cardboard

Horizontal balers offer a powerful solution to compact large volumes of waste into compact, stackable bales.

- Compact design: Takes up only 5 m²

- Compacts both cardboard and plastic

- Continuous filling with automatic start

- Semi-automatic bale ejection

- Press & Hold function for constant pressure

Cardboard baler hire and purchase options with Mil-tek

At Mil-tek, we offer flexible solutions for acquiring your cardboard baler. Whether you’re considering cardboard baler hire or outright purchase, we ensure a seamless experience tailored to your business needs.

- Hire a cardboard baler starting from as little as 12 months.

- Purchase a baler outright to maximize long-term savings.

- Buy a refurbished baler cost-effective solutions

All options come with:

- Professional installation for immediate use.

- Operator training to ensure safety and efficiency.

- Ongoing servicing to keep your operations hassle-free.

Benefits of renting a cardboard baler:

- Low upfront cost with predictable weekly payments.

- Flexibility to up- and downgrade as your needs change.

- Maintenance and servicing included for peace of mind.

Benefits of buying a cardboard baler:

- Greater cost savings over the long term.

- Full ownership of the equipment.

- Ideal for businesses with consistent, high-volume needs.

Frequently Asked Questions

1. What is a cardboard baler and how does it work?

You simply load the cardboard in the chamber, close the door, press the start button, and the machine starts compacting. Once full, the bale is tied off and removed.

2. What types of cardboard balers are available, and which one do I need?

Small businesses typically choose vertical balers, while high-volume operations benefit from horizontal or mill-size balers.

The right machine depends on things like waste volume, available space, and required bale weight.

3. What size and weight are the bales?

- Small balers: 40–80 kg bales

- Medium balers: 100–200 kg

- Mill-size and horizontal balers: 300–600 kg

4. What are the benefits of using a cardboard baler?

It also cuts labour time spent flattening cardboard and can generate revenue if you sell baled cardboard to recyclers.

Cleaner, safer, and more sustainable operations are common benefits.

5. Can I bale only cardboard, or other materials too?

For best recycling quality, materials should always be clean, dry, and properly sorted. Mixing different material types is not recommended.

6. What are the safety and maintenance requirements?

7. How much can I earn from selling baled cardboard in the UK?

- Clean mill-size bales (400–600 kg) typically command the highest rebate

- Smaller or lighter bales may still be collected, but offer lower prices or free collection only

8. Do I need planning permission or special installation requirements for a cardboard baler in the UK?

- The baler is positioned on a flat, solid floor

- There is enough overhead clearance for the press plate to operate

- The baler is installed in a safe, accessible area for operators and waste collectors