Waste handling in manufacturing

This page explores how optimised waste handling can improve workflow, reduce risk and costs, and enhance overall efficiency in the production sector.

Manufacturing Waste Solutions

As a manufacturer, you can reduce costs, save space, and boost efficiency by integrating Mil-tek’s sector-specific balers and compactors directly into your production workflow.

✅ Get expert advice on the right baler(s) for your production → Talk to a Mil-tek consultant

✅ Explore models for cardboard, plastic, polystyrene and more → Browse all balers and compactors

The hidden cost of packaging waste in manufacturing

Packaging waste like cardboard, plastic film, and EPS builds up fast in manufacturing. Without compacting it at the source, it clutters workflows, increases handling, and drives up costs.

📌 Did you know?

Handling waste can cost up to 10 x more than disposal!

How can manufacturers reduce waste

Lean principles drive efficiency by reducing waste, improving flow, and supporting continuous improvement. But waste isn’t just excess time or inventory. It includes the physical by-products of daily operations.

Treating waste handling as part of the value stream – with balers, compactors, and smart equipment placement – helps cut clutter, reduce motion, and create a cleaner, more efficient workspace.

Key ways to put Lean into practice include:

- Regular waste audits

-

Setting clear waste reduction goals

-

Assigning responsibility

-

Training staff on best practices

- Installing waste-minimizing equipment in key locations

Waste Management Solutions for the Manufacturing Industry

Book a free waste audit with us to determine the ideal solution for your facility.

Or explore baler solutions for common manufacturing waste materials below.

Cardboard waste in production

Cardboard waste clogs manufacturing efficiency. Mil-tek balers – from the compact A305 to the high-volume E819 – cut the clutter, automate the process, and reclaim your space.

View all cardboard balers

or specific industry recommendations below:

A305 Vertical Baler

Usage:

Cardboard & Plastic

Power:

Pneumatic, 4 tonnes pressing force

Key Attributes:

- • Up to 175 kg bales

- • 90 % compaction

- • 0.85 m² footprint

- • Automated bale-out

A509 Vertical Baler

Usage:

Cardboard & Plastic

Power:

Pneumatic, 4 tonnes pressing force

Key Attributes:

- • Up to 300 kg bales

- • 90 % compaction

- • 1.5 m² footprint

- • Adjustable bale size

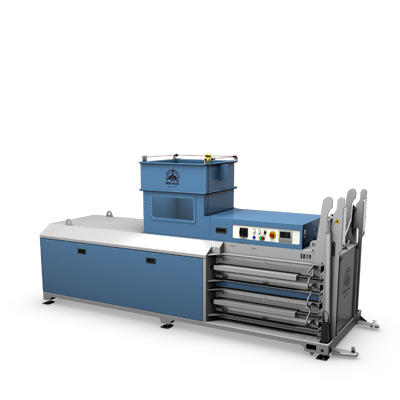

E819 Horizontal Baler

Usage:

Cardboard & Plastic

Power:

Electric, 25 tonnes pressing force

Key Attributes:

- • Up to 400 kg bales

- • 90 % compaction

- • 5 m² footprint

- • Continuous filling / automatic start

Plastic waste in production

Soft plastic waste is a constant in manufacturing, from stretch film to plastic wrap and bags. Mil-tek provides powerful solutions for soft plastic waste, with balers built to handle everyday demand and shrink volume by up to 90%.

View all plastic balers

or specific industry recommendations below:

A406 Vertical Baler

Usage:

Plastic & Cardboard

Power:

Pneumatic, 8 tonnes pressing force

Key Attributes:

- • Up to 225 kg bales

- • 90 % compaction

- • 1 m² footprint

- • Automated bale-out

E619 Vertical Baler

Usage:

Plastic & Cardboard

Power:

Electric, 25 tonnes pressing force

Key Attributes:

- • Up to 400 kg bales

- • 90 % compaction

- • Low height

- • No hydraulics

H600 Vertical Baler

Usage:

Plastic & Cardboard

Power:

Hydraulic, 60 tonnes pressing force

Key Attributes:

- • Up to 500 kg bales

- • 90 % compaction

- • Mill size bales

- • Automatic door operation / bale ejection

Polystyrene waste in production

EPS is widely used in manufacturing for protective packaging. Mil-tek’s EPS1000 and larger EPS2000 compactors turn bulky EPS waste into dense blocks, cutting down storage needs and disposal costs.

View polystyrene compactors

or specific industry recommendations below:

EPS1000 Compactor

Usage:

Polystyrene

Power:

Electric, 3 × 400 V, 1.8 kW

Key Attributes:

- • Volume reduction 40:1

- • Makes dense blocks of up to 300 kg

- • Compacts up to 15 kg./hour

- • Sell blocks to recyclers

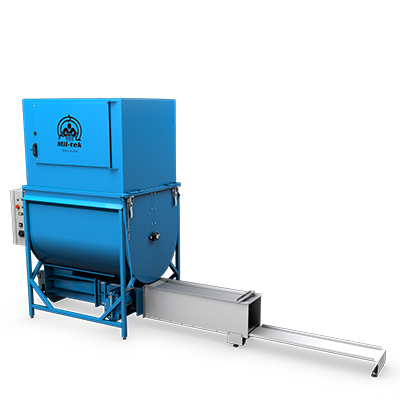

EPS2000 Compactor

Usage:

Polystyrene

Power:

Electric, 3 × 400 V, 1.8 kW

Key Attributes:

- • Volume reduction 40:1

- • Makes dense blocks of up to 300 kg

- • Compacts up to 70 kg./hour

- • Sell blocks to recyclers

Food production waste

In hygiene-critical food production, waste needs clean, safe handling. Mil-tek’s stainless steel, oil-free balers – such as the 2205S and 2306S – compact cardboard and plastic without compromising sanitation.

View specific industry recommendations below:

2205S Baler

Usage:

Cardboard & Plastic

Power:

Pneumatic, 2 tonnes pressing force

Key Attributes:

- • Up to 120 kg bales

- • 90 % compaction

- • Stainless steel & no hydraulics

- • Small footprint

2306S Baler

Usage:

Cardboard & Plastic

Power:

Pneumatic, 8 tonnes pressing force

Key Attributes:

- • Up to 250 kg bales

- • 90 % compaction

- • Stainless steel & no hydraulics

- • Automated bale-out

By baling your manufacturing waste, you turn it into compact, stackable, and recyclable bales – reducing storage needs, saving time, and lowering transport expenses.

Let’s design your waste solution!

Book a free site survey and discover smarter waste solutions for your manufacturing facility.

We can help you integrate Lean practices beyond the production line

While Lean methodology is well embedded on the production floor, waste handling is often still disconnected from the continuous improvement mindset.

By integrating balers and compacting waste at the source, you can:

- Eliminate “waste walking” and double-handling

- Keep doors closed to reduce airborne contamination

- Shorten disposal time and free up staff hours

- Boost productivity and improve operational efficiency

- Minimise forklift traffic and reduce manual transport risks

TIP!

Reduce dust build-up in rip-and-tip areas with our dust extraction solution, designed to fit directly on your baler.

Get in touch 📞

We’re ready to help your manufacturing business

manage waste more efficiently!

Fill out the form and we’ll return shortly, or call us.