Automotive Waste Management

This page explores how efficient automotive waste management can free up space, lower costs, and

keep your team focused on billable work.

Smart Automotive Waste Solutions to Streamline Your Workshop

At Mil-tek, we help automotive workshops reduce operational costs, maximize floor space, and improve workflow efficiency through smarter waste management. With our balers and compactors, your team can focus less on handling waste, and more on profitable, billable work.

✅ Get started with a free on-site consultation

→ Schedule your Mil-tek site assessment

✅ Find the ideal baler for your automotive workshop

→ Explore our full range of balers and compactors

Let Your Auto Technicians Wrench – Not Spending Time on Waste

In a fast-paced automotive shop, your technicians are your most valuable resource. Their expertise belongs under the hood—not wasted on breaking down boxes or managing trash.

But every day, packaging, shrink wrap, and used containers start to pile up. The clutter eats into your workspace, consumes time, and fills bins in no time. When your techs are navigating around waste or hauling garbage instead of fixing vehicles, your shop loses efficiency—and profit.

📌 Every 5 minutes spent handling waste

is 5 minutes missing to a customer job!

How Automotive Workshops Can Reduce Waste and Drive Higher Profits

Waste reduction isn’t just about keeping a clean shop – it’s about taking back time, space, and revenue. Here’s how auto repair shops can regain control over their waste flow and improve the bottom line:

- Spot the waste hotspots: Take a walk through your facility and pinpoint where waste builds up—often near service bays, parts counters, or receiving zones.

- Strategic bin placement: Place purpose-sized plastic bag stands right where waste is generated. The closer and easier it is to dispose of cardboard or plastic, the faster your techs can stay focused on repairs.

- Deploy balers at the source: Use compactors or balers directly in high-waste zones. Instead of flattening and stacking boxes, waste is compacted immediately—saving space and cutting down on trips to outside dumpsters.

- Shift the mindset: Coach your team to view waste as lost productivity – not just clutter.

Automotive Waste Management Solutions

Book a free waste audit with our experts and discover the right-fit solution for your automotive operation.

Otherwise check out our range of balers designed to handle the most common waste materials found in auto repair environments:

Cardboard Waste in Automotive Workshops

Cardboard from parts packaging and deliveries can build up quickly in a busy automotive environment. Mil-tek balers help you stay organized and efficient by compacting cardboard right where it’s generated.

Explore our cardboard balers or find the best solution for your specific automotive needs below:

A102 Vertical Baler

Usage:

Cardboard & Plastic

Power:

Pneumatic, 2,5 tonnes pressing force

Key Attributes:

- • Up to 100 kg bales

- • 90 % compaction

- • 0.45m² footprint

- • Ergonomic working height

A406 Vertical Baler

Usage:

Cardboard & Plastic

Power:

Pneumatic, 8 tonnes pressing force

Key Attributes:

- • Up to 225 kg bales

- • 90 % compaction

- • 1 m² footprint

- • Wide chamber for larger materials

E319 Vertical Baler

Usage:

Cardboard & Plastic

Power:

Electric, 15 tonnes pressing force

Key Attributes:

- • Up to 100 kg bales

- • 90 % compaction

- • Almost silent running

- • Less than 2 metres high

Tackling Plastic Waste in Automotive Workshops

From parts packaging to protective film, plastic waste can pile up quickly in an automotive shop. Plastic is efficiently compressed at the sourc with Mil-tek balers – keeping your workspace clean, safe, and focused on productivity.

Browse our range of plastic balers or find the right-fit solution for your workshop below:

A305 Vertical Baler

Usage:

Plastic & Cardboard

Power:

Pneumatic, 4 tonnes pressing force

Key Attributes:

- • Up to 175 kg bales

- • 90 % compaction

- • Footprint under 1m²

- • Automated bale-out function

A509 Vertical Baler

Usage:

Plastic & Cardboard

Power:

Pneumatic, 8 tonnes pressing force

Key Attributes:

- • Up to 400 kg bales

- • 90 % compaction

- • Low height

- • No hydraulics

E319 Vertical Baler

Usage:

Plastic & Cardboard

Power:

Electric, 15 tonnes pressing force

Key Attributes:

- • Up to 100 kg bales

- • 90 % compaction

- • Almost silent running

- • Built-in bale ejection

Metal Cans & Oil Buckets: Compact Waste at the Source

The Mil-tek Can Crusher easily crushes oil buckets, paint cans, and metal containers up to 30L. This compact machine reduces volume by up to 90%, conserves valuable floor space, safely manages hazardous fluids, operates quietly, and fits seamlessly into any workshop layout.

Explore our can crushers or Find the right solution for your needs below:

A101 Can Crusher

Usage:

Cans & Buckets

Power:

Pneumatic, 2,2 tonnes pressing force

Key Attributes:

- • Cans and buckets up to 30L

- • Up to 90 % compaction

- • Can handle hazardous fluids

- • Use indoors or out

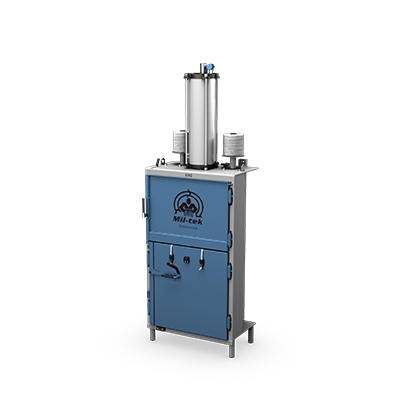

2101s Can Crusher

Usage:

Cans & Buckets

Power:

Pneumatic, 2,2 tonnes pressing force

Key Attributes:

- • Stainless steel

- • Cans and buckets up to 30L

- • Up to 90 % compaction

- • 0.27 m2 footprint

Don’t Let Unmanaged Waste Steal Valuable Workshop Space

Schedule a free on-site survey today, we’ll help you identify the ideal waste solution tailored to your workspace.

Check out the video!

An automotive workshop freed up enough space for two additional EV charging bays, simply by using Mil-tek balers.

Get in touch!

We’re here to help your auto repair shop manage waste smarter.

Fill out the form and we’ll get back to you shortly, or give us a call.