Cardboard Compactor Guide – Best practices for cardboard compaction

Businesses that consistently generate cardboard waste require effective compaction strategies

A widely adopted solution among many businesses in different sectors is the implementation of one large cardboard compactor.

This is often positioned outside of company buildings to manage and minimize the bulk of daily cardboard waste.

Here’s why a conventional cardboard compactor may not always be the ideal choice

Having one large cardboard compactor presents several disadvantages that may hinder operational efficiency and reduce cost-effectiveness:

- Transporting waste to the compactor poses logistical challenges, especially for larger facilities or those with substantial cardboard waste. This task is time-consuming, diverting employees from their primary responsibilities.

- Positioning the compactor outside can complicate transportation, reduce safety, and cause delays during bad weather.

- Contracts for cardboard compactors often lack flexibility, with fixed pickup schedules that don’t adjust to sudden increases in waste. This can result in overflows or costly unscheduled pickups.

Enhance Lean efficiency: Optimize cardboard waste management with a baler

Indoor balers, placed around the facility where waste occurs, offer several advantages over large compactors, enhancing business operations significantly.

Balers embody lean waste management principles, minimizing not just material waste but also time and movement. This integration leads to more efficient workflows, reducing unnecessary actions and delays, boosting productivity, and supporting sustainability by lessening the environmental toll of waste transport.

Lean waste management also promotes continual improvement. Indoor balers are adaptable and scalable, evolving with the business to optimize waste processes continuously. This flexibility ensures efficient, responsive waste management that adjusts to business needs without excess capacity or resource underutilization.

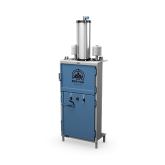

Explore a diverse range of cardboard balers below:

4 Benefits of using indoor cardboard balers:

1. Enhanced operational effectiveness

Streamlined waste handling:

Indoor balers are generally situated nearer to where the waste is generated, minimizing the time and effort required for employees to transport cardboard waste. Their close proximity facilitates faster and more frequent disposal, especially beneficial during busy times.

Uninterrupted performance:

Indoor balers operate independently of outside weather conditions, unlike a large compactor placed outdoors. They can function continuously, unaffected by rain, snow, or extreme temperatures, ensuring steady and delay-free waste management.

2. Improved cost efficiency

Reduced transportation costs:

Using an indoor baler allows companies to accumulate compacted bales until enough gather to warrant a collection, cutting down on the frequency and expense of waste pickup.

Profit from recycling:

Compacted bales of cardboard are typically more desirable in the recycling market than loosely compacted materials. Businesses can sell these bales to recyclers, transforming waste management into a profit-making endeavor.

3. Improved space management

Optimal space usage: Indoor balers can be seamlessly incorporated into a business’s current spatial arrangement, making better use of vertical space. This smaller footprint enables businesses to fully utilize their operational areas without requiring substantial outdoor space.

Tailored baler options: Balers are available in a range of sizes and capacities, offering businesses the opportunity to select a model that perfectly matches their specific space and volume needs.

4. Environmental advantages

Decreased environmental impact: Indoor balers reduce the number of required pickups and enable more efficient scheduling, which helps cut down on carbon emissions related to waste transportation. Enhanced recycling efficiency and less frequent transportation contribute to a reduced overall environmental footprint.

Reduced cross contamination: Balers placed indoors contribute to a neater and more controlled waste handling environment. This improved containment lessens the risk of environmental pollution and avoids issues such as litter or pests often linked with outdoor compactors.

We’re here to assist you!

Contact us to discover how Mil-tek can help your business reduce time, space, and costs through efficient cardboard waste compaction.

Complete the form, and we we’ll return soon.